MENU

- Home

- About Us

- Products

- News

- Typical Cases

- Certificate of honor

- Plant Landscape and Appearance

- Contact Us

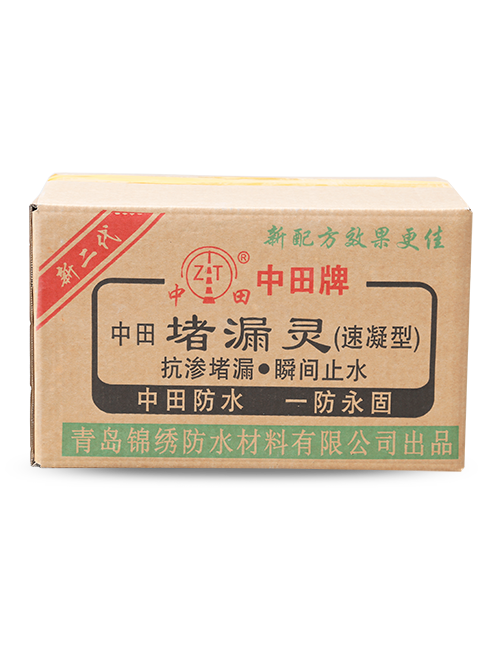

The plugging material is a dampproofing, anti-seepage and leaking stoppage material as well as an excellent adhesive developed based on domestic and overseas advanced technologies.

Product overview

The plugging material is a dampproofing, anti-seepage and leaking stoppage material as well as an excellent adhesive developed based on domestic and overseas advanced technologies.

The product can control seepage, stop leakage and water instantly;

It is applicable to both the water contacting face and the back face, facilitating construction;

It can be applied to water drinking works;

The curing time is adjustable. And waterproofing and adhesion can be finished in one step.

Application scope

It is applicable to waterproofing of non-water seepage surface as well as ceramic tile, mosaic tile and cement paste plastering. For large-area waterproofing, composite waterproof coating produced by our company should be used to form an elastic waterproof layer.

Product usage

The product can be applied for repair of seepage and leakage of buildings or structures made of bricks, stones and concrete, especially for water seepage and plugging of underground works. It can enable waterproofing and adhesion to be completed in one step.

Construction process

Non-water seepage surface construction (delayed coagulation type leakage repair material)

(1) Base treatment: The base must be fully wetted and saturated (without ponding) and should be firm, clean and level. Uneven places can be leveled with cement mortar firstly.

(2) Ingredients: Non-water seepage surface should apply "delayed coagulation type plugging material". The powder and water can be mixed in 1:0.3 evenly at a low speed until it becomes a slurry without lumps.

(3) Construction: After the base layer is treated properly, the delayed coagulation slurry should be scrapped with a scraper or trowel. After the coating is hardened (no fingerprint is left by pressing it with the fingers), the coating should be maintained timely with spray. 90min after pavement of the first layer of coating, the second layer should be paved along the direction vertical to the first layer. The third layer can be paved as needed. After pavement of all the coating layers, it should be maintained in a wet way for 48h (spraying water or covering with a wet thing).

Water seepage surface construction (quick coagulation type leakage repair material)

(1) Base treatment: The base surface must be damp, firm, clean and level. Uneven places can be leveled with quick coagulation type leakage repair material mixed with two times of medium sand. For the base surface with severe water seepage, a water diversion hole may be made at a proper position to relieve pressure and divert leaked water out.

(2) Ingredients: Water seepage surface construction should apply the quick coagulation type leakage repair material. The powder and water can be mixed in 1:0.3 evenly at a low speed until it becomes a slurry without lumps. Not too many materials should be prepared at one time, in case of curing and waste.

(3) Construction: After wiping the base surface with dry cloth, the upper layer of material should be plastered quickly with a trowel (seeped water can be treated later): After the surface is cured (no fingerprint left by pressing it with fingers), constructors can wipe the surface to make it dry. If there is still a large area of seeped water when paving the second layer of materials, the third layer of materials can be paved with the same method. If there is only seeped water locally, constructors only need to add a layer of coating on the water seepage position until no water is seeped, and then block the water diversion hole. It should be maintained in a wet way for 48h (spraying water or covering with wet things).

Quick repair of water leakage holes (quick coagulation type leakage repair material)

(1) Base treatment: Chisel the leakage position into an inverted horn shaped hole.

(2) Ingredients: Quick repair of water leakage holes must apply the quick coagulation type leakage repair material. The constructor can mix powder and water in 1:0.2 and then rub it repeatedly to make it into a lump. The sealing material should be made by mixing power and water (1:0.3) evenly into putty.

(3) Construction: The constructor can fill the lump to be cured quickly into the water leakage hole and then compact it with a hammer and rod. After conforming that there are no leakage, scrape and press the extended parts around the hole within 10cm again, spray frog for conservation in time. Small holes should be repaired first, followed by large holes.