MENU

- Home

- About Us

- Products

- News

- Typical Cases

- Certificate of honor

- Plant Landscape and Appearance

- Contact Us

This product is a bi-component chemical reaction solid waterproof material. Component A is prepolymer of isocyanate for end sealing, and component B is colored liquid composed of plasticizer, curing agent, thickener and filling agent. Component A and component B are mixed in a certain proportion, mixed evenly and then brushed on a certain plane. After several hours of reaction and curing, an elastic, flexible and durable waterproof coating will be formed.

Product overview

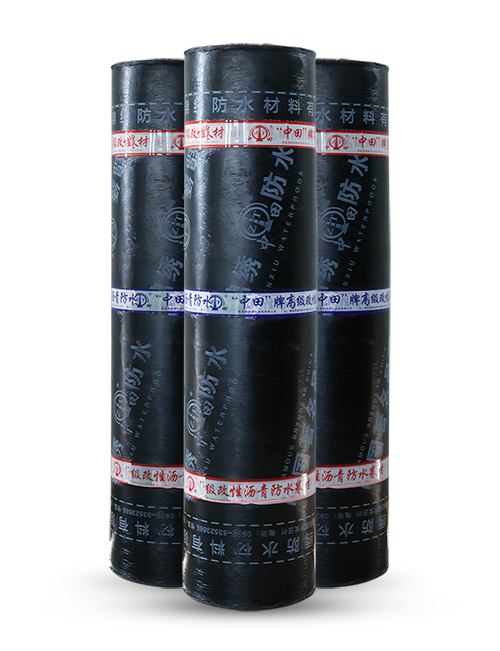

SBS elastomer modified asphalt waterproof roll is manufactured by mixing and grinding in a special machine. It takes SBS (styrene-butadiene-styrene) thermoplastic elastomer modified asphalt as the dip coating material, the high-quality polyester felt, glass fiber felt, glass fiber reinforced polyester felt as the base, the fine sand, mineral pellets, PE film, aluminum film, etc. as the cladding materials.

APP plastic modified asphalt waterproof roll is manufactured by advanced technology. It takes APP (random polypropylene) or APAO, APO (polyolefin polymer) modified asphalt as the dip coating material, the high-quality polyester felt, fiberglass mat as a base, and the fine sand, mineral particles (film) material, PE film as the cladding materials.

Species and specification

According to physical indicators: Type I and type II;

According to the base: PY, G and PYG;

According to the facing material: PE film, color sand, shale piece and fine sand;

According to the material thickness: 2mm, 3mm, 4mm and 5mm, etc.

Product features

Strong waterproofness;

High tensile strength, large elongation, good dimensional stability, strong adaptability to the deformation and cracking of the base layer;

good high temperature resistance performance; SBS is suitable for building waterproofing in a lower temperature environment, and APP is suitable for building waterproofing in high temperature environment;

puncture resistance, breakage resistance, tear resistance, corrosion resistance, mildew resistance, weathering performance;

convenient for construction, and construction by the heat fusion method can be operated at all seasons; seams are reliable.

Construction methods

Heat fuse method, cold adhesion method and hot-cold combination method: Roll can be constructed by heat fusion method or cold adhesion method, or combine the hot and cold method, i.e. the cold adhesion method is used for large areas, and the lap seams are constructed by the hot-melt method.

Heat fusion method: Bake the roll bottom and the base surface with a flame gun or blowtorch to make the asphalt on the roll surface melt. Unfold the roll while baking, compress the roll with a compression roller to make the asphalt and the base or roll adhere firmly.

Cold adhesion method: Brush adhesive evenly onto the waterproof base and roll, adhere the roll after it is properly dry, compress with a compression roller to squeeze air below the roll out, make the roll level and compact and make asphalt adhere to the base or roll firmly.

Construction machinery and auxiliary materials

Construction tools for clearing the waterproofing base: Shovel, broom, dust blower, hand hammer, steel chisel, etc.

Construction tools for roll pavement: Scissors, tape, line snapping box, scraper, hairbrush, compression roller.

Dedicated hot melting machinery: Single-head or multi-head hot melting spray gun or blowtorch.

Auxiliary materials: Base treatment agent, roll adhesive, sealing strip.

Roll paving

Before construction, acceptance base layer needs to be cleaned, and dusts on the corners need to be blown.

The base layer treatment agent must be brushed evenly, and do not repeat the brushing.

After the base layer treatment agent is dried, first of all, additional layers should be laid on the roof waterproofing project and underground waterproofing project according to the design requirements.

Determine the laying order and direction of rolls, and snap on the base layer, and then lay the rolls. The rolls at different parts should be pasted according to the following requirements of construction.

Roof: The rolls are pasted with the base layer by point cohesion or strip cohesion methods; 800mm around the roof should be fully pasted; Paste area on the slope roof is more than 70%, and rolls should be 100% pasted with each other.

Basement base slab: The rolls and the base layer can be fully pasted, pasted by points, strips or by empty spreading, but the rolls must be fully pasted with each other.

Additional layer: Generally, the roll should be fully adhered to the base. For deformed canopy, the roll can be paved without using adhesive.

The laying order is high-span at first, followed by low-span; for the same height, lay the far position before the close position; for the same plane, start from the lower position.

Roof laying direction:

For the slope <3%, lay in the direction that is parallel to the roof.

For the slopes 3% ~ 15%, lay in the direction that is parallel or perpendicular to the roof.

For the slope> 15% or in case of vibration, lay in the direction that is perpendicular to the roof.

In case of being parallel to the roof, the lap seam should follow the direction of the downstream water; in case of being perpendicular to the roof, the lap seam should follow the main wind direction.